How to choose a waterjet marble medallion

The processing principle of stone waterjet parquet is: use computer-aided drawing software (CAD) and computer numerical control programming software (CNC) to convert the patterns designed by people into NC programs through CAD, and then transfer the NC programs to the numerical control water cutting machine. According to the design requirements, the selected various natural stones are cut into independent graphic components with a numerical control water cutting machine. Then the various stone pattern parts are manually spliced, repaired and bonded into a whole, and finally polished, so that the entire waterjet mosaic processing is completed.

Size: large size or customized

Material: Marble

Insurance: Covers all risks

Place of Origin: Hebei, China

Packing: sturdy wooden crate

Service: Customized and acceptable

Technology: Natural

Advantages: factory direct sales, door-to-door delivery

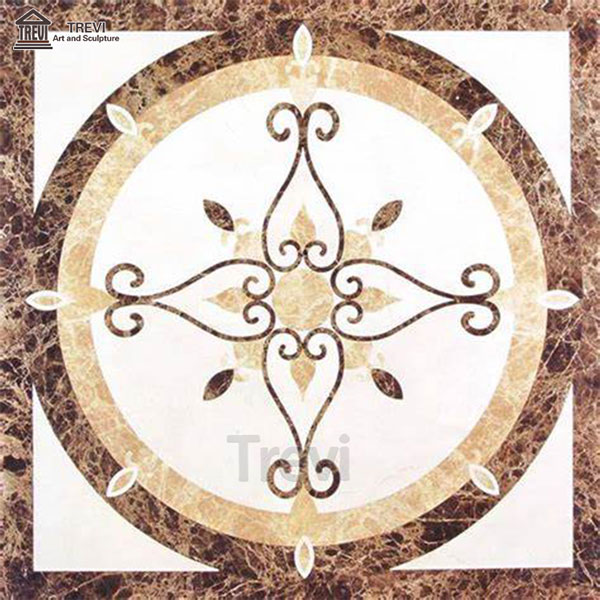

Divided according to the geometric shape of the parquet: rectangular and square parquet; round parquet and oval parquet; fan-shaped parquet; regular polygon parquet.

Divided by installation area: lobby parquet; guest room parquet; lounge, coffee shop, piano bar parquet; living room, dining room parquet; entrance parquet; bathroom parquet; stairs and stepping parquet.

Divided by processing materials: marble mosaic, granite mosaic, artificial stone mosaic, mixed material mosaic, ceramic tile mosaic.

Mixed material mosaics: mosaics processed by different materials, including marble + granite mosaics, marble + artificial stone mosaics

Flower, artificial granite+artificial quartz stone mosaic, marble+metal mosaic, marble+tile mosaic, marble+shell.

Stone waterjet parquet is a difficult technique for stone processing. It requires precision, accuracy, integration, and the effect of harmony between man and nature. It mainly relies on machinery and equipment, as well as design capabilities and technical personnel’s ability to digest drawings.

In fact, stone mosaics are relatively simple, and simple patterns can generally be processed by hand. Complex patterns generally have to be processed by water jet machining, but not all complex patterns can or can only be processed by water jet machining. For example, the stone mosaic inlaid on a flat or arc board cannot penetrate the bottom plate. This type of stone mosaic cannot be machined with a water jet. part. It is also useful to process the bottom plate with a sandblasting machine. Of course, the inlaid parts are not necessarily stone, they can be gems, glass, shells, metal, etc.

Please feel free to contact us, we will provide customers with good memories.